Weldments

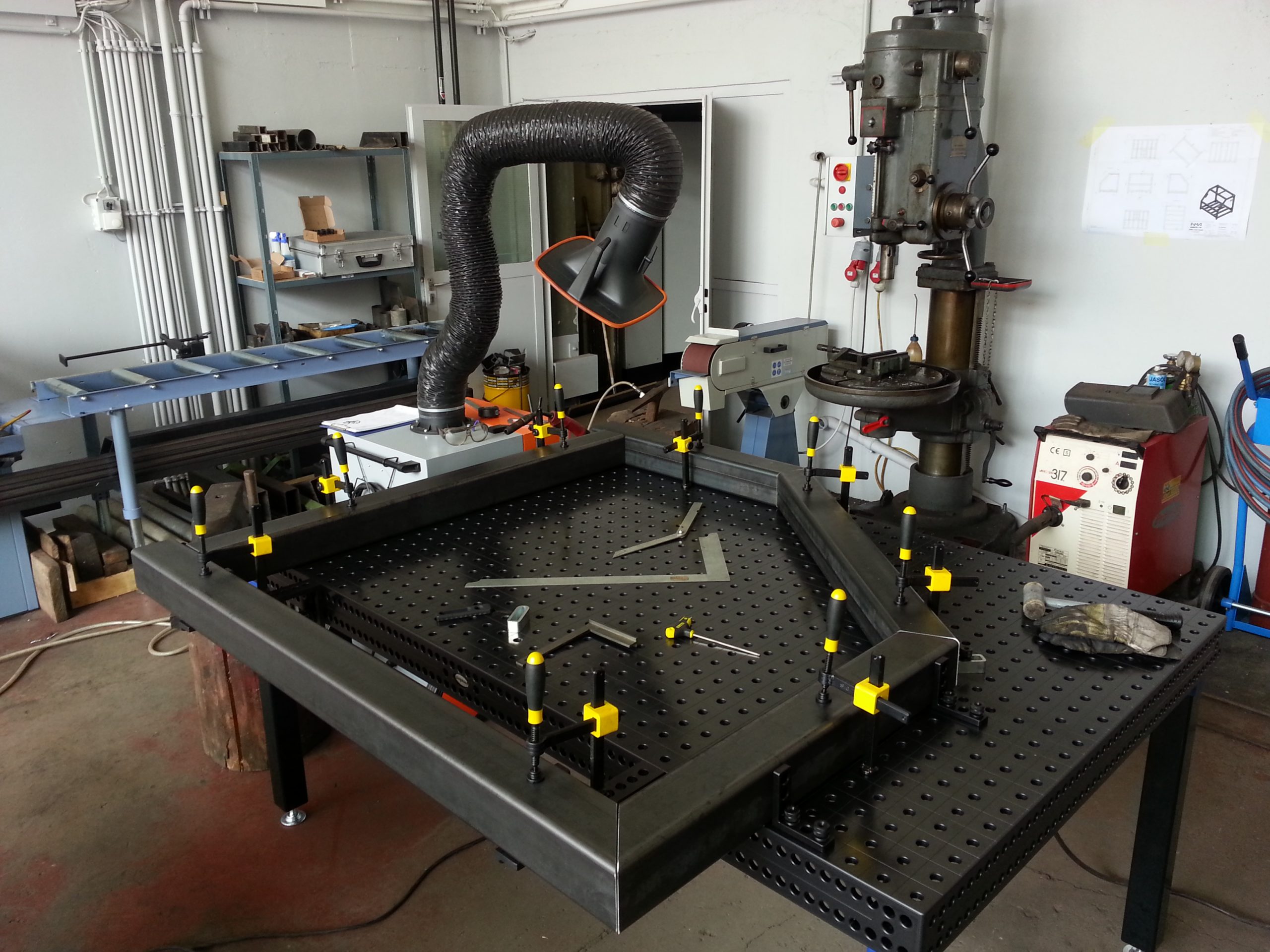

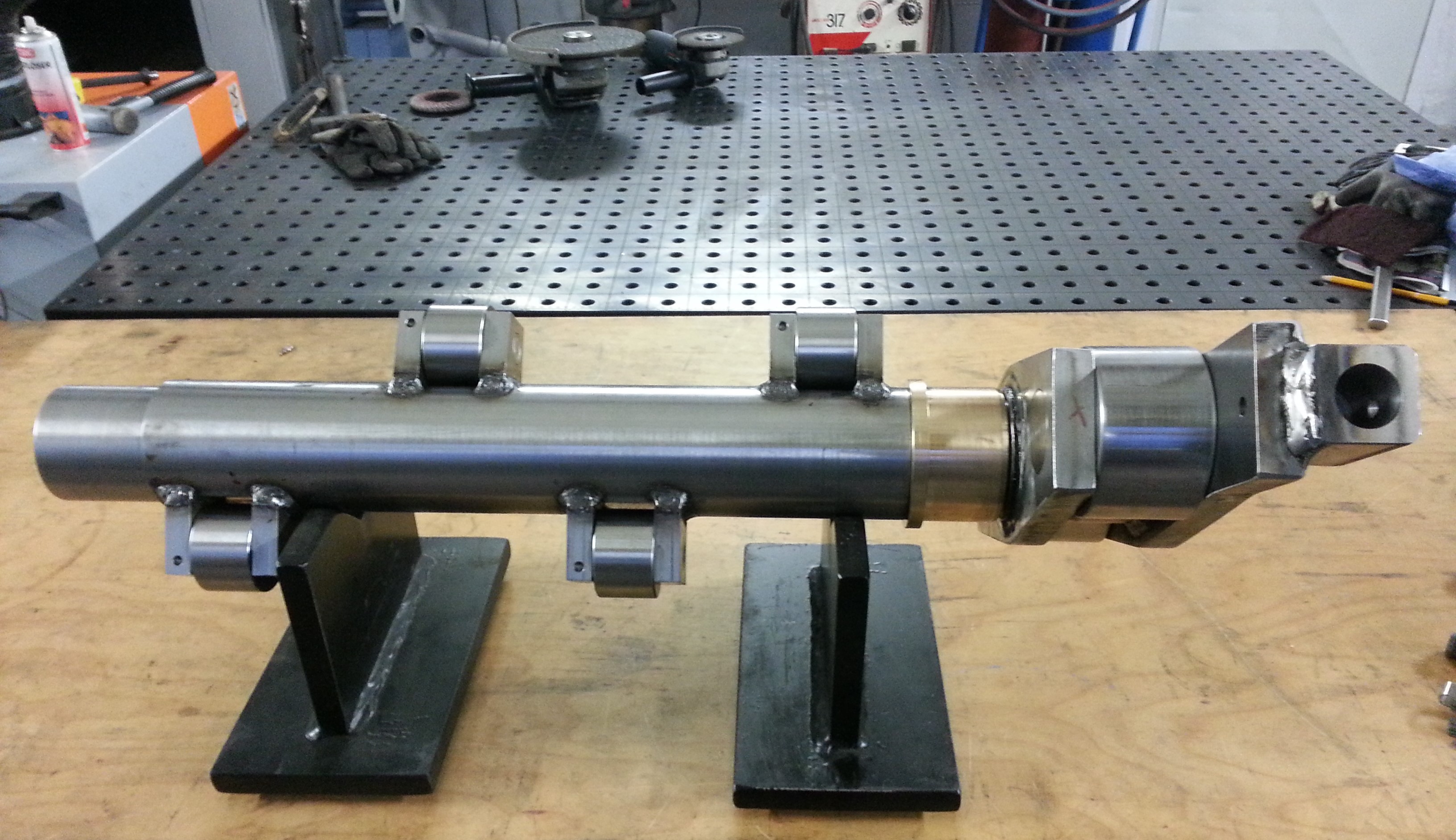

Our production technology is specialized for the manufacture of precise and multi-dimensional, stable weldments.

Precisely processed and neatly welded metal constructions for machines, plants or mechanical systems is one of our strength in the field of contract manufacturing.

We also offer production and assembly of complete, highly complex assemblies.

Below you can have a brief overview of our technical equipment, machines, and facilities:

Extract of our state-of-the-art machinery:

- Welding table (flatness: 0.1mm / m)

- Inert gas welding machine (MIG / MAG, 300A)

- Electric welder (portable MMA welding machine, 150A)

- Lathe (max. workpiece dimensions: turning diameter ø: 540mm / length: 1600mm)

- Column drill (spindle taper MK4, drilling performance: ø 50,5mm in steel)

- Band saw and grinder

- Forming press

- Magnetic drill machine

- … and much more!!!

- As well as a fully equipped workshop vehicle.